Protection of Electric Motors

Protection of electric motors is important to ensure long life and safe operation of the motor. Protection methods include thermal protection, overcurrent protection, overvoltage protection, and overload protection. Thermal protection is used to prevent the motor from overheating. Overcurrent protection prevents the motor from exceeding normal current limits. Overvoltage protection protects against voltage surges to prevent damage to the motor. Overload protection prevents mechanical loads on the motor from exceeding a certain limit. These protection measures increase the operating efficiency of the motor, prevent malfunctions, and ensure safe operation. Regular maintenance and cleaning are also important for motor protection.

How to Protect Electric Motors?

The protection of electric motors is of great importance to ensure long life and safe operation of the motor. Various methods are used for this protection:

• Thermal protection: Thermal protection devices are used to prevent motor overheating. These devices automatically switch off the circuit when the motor overheats.

• Overcurrent protection: If the motor exceeds normal current limits, overcurrent protection circuits are activated to protect the motor.

• Overvoltage protection: Surge protection devices are used to prevent damage to the motor. These devices protect the motor against voltage surges.

• Overload protection: Overload protection systems are activated to protect the motor if the mechanical loads on the motor exceed a certain limit.

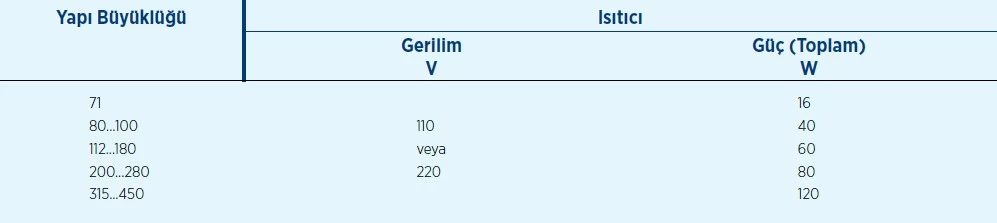

Regular maintenance and cleaning are also necessary to protect the engine. If the motor is to operate in an open environment, protective measures must be taken. Special protective paint can be used, the degree of protection must be IP 56 and the winding heads must be protected against excessive moisture. For vertical installations open to the atmosphere, additional covers or sealing gaskets can be used to prevent the motor from leaking water.

Protection Classes of Electric Motors

• IP55: Motors with this protection class offer complete protection against dust and external objects must not be larger than 1 mm in diameter. They also protect water jets. These motors are generally used in indoor applications.

• IP56: Motors belonging to the IP56 protection class are designed for use in harsh operating environments and outdoor applications. These motors provide a high level of protection against dust and water. Thus, they ensure the safe and efficient operation of the motor. They are resistant to high-pressure water jets and offer resistance to harsh weather conditions.

• IP65: Motors in this protection class are fully protected against dust and resistant to low-pressure water jets. It prevents damage when the motor is exposed to low-pressure water. However, it does not protect against high water pressure or immersion in water. IP65 motors can be used indoors and outdoors.

• IP66: Motors with the IP66 protection class provide full protection against dust and do not allow dust to enter. They are also resistant to high-pressure water jets. They provide protection even if the motor is exposed to high-pressure water or submerged under water. These motors are designed for use in harsh outdoor applications and humid environments.

Protective Measures in Gamak Electric Motors

The degree of protection of electric motors is indicated by IP (Ingress Protection) classification by TS 3209 EN 60034-5 standard. IP classification is an abbreviation consisting of the initials of the English words "Ingress Protection" and consists of two characteristic numbers. For example, protection classes IP55 and IP56 provide complete protection against random touching of live parts inside the motor. They also protect against the accumulation of damaging amounts of dust. It prevents the ingress of dust in quantities that could affect the operation of the motor. These protection classes also protect against water. The engine is protected against damage caused by water spraying on it from any direction. It also prevents water from entering the motor during storms or pressurized spray water on the ship deck. Our production also includes electric motors with IP65 and IP66 protection classes in line with customer demands. The IP65 protection class ensures that the motor is completely protected against dust and is resistant to low-pressure water jets. The IP66 protection class provides full protection against dust as well as protection against high-pressure water jets. Motors with these protection classes can be used safely and robustly in harsh working environments or outdoor applications. The protection class to be selected should be determined by the environment and requirements where the motor will be used.

The Temperature in Electric Motors

The operating temperature of electric motors is usually determined depending on the design and intended use of the motor. However, in general, the motor temperature is considered a warm-up condition and should be kept within a certain temperature range. Under normal operating conditions, the temperature of the motor should generally average between 70 and 90 degrees Celsius. This range is considered appropriate to keep the engine running efficiently. However, excessive increases in the temperature of the engine can cause damage to the engine and reduce its performance. Therefore, it is important to monitor the temperature of the engine and keep it under control with appropriate cooling methods.

Causes of Overheating of The Electric Motor

Overheating of electric motors can have various causes. These include high current flow, overvoltage, insufficient cooling, high running speed, mechanical problems, and low efficiency. High current flow can overheat the coils inside the motor. Overvoltage can cause more power to be applied to the motor than normal. Inadequate cooling can cause heating if the airflow around the motor is insufficient or the cooling system is ineffective. High operating speeds also increase friction and energy loss, triggering heat build-up. Factors such as mechanical problems, friction, high bearing, and high vibration can also cause the engine to overheat

Click here to use the GAMAK electric motor selection tool to select the right electric motor for your needs.