Double Speed Motors

In induction motors, motors that can obtain two or more power and speed from a single size of the structure are called "multi-speed motors". Two-cycle motors are generally manufactured in two different power and cycles obtained from a single winding placed on the stator or from two separate windings.

These motors are divided into two according to the winding shape;

1. Dahlander Linked Motors:

They are motors that can obtain two different revolutions at a ratio of only 1:2 from a single winding placed on the stator. The 4/2 and 8/4 pole motors included in the operating values pages are motors with dahlander winding.

2. Two Separately Wound Motors:

It consists of 2 separate windings for 2 different circuits placed on the stator. This design is generally used when pole ratios are inappropriate. The 6/4-pole motors included in the operating values pages are motors with two separate windings.

Please consult for the manufacture of 3 or 4-speed motors that can be obtained by using both winding designs together.

Design of two-cycle motors

Two-cycle motors are generally designed for two different applications.

1. Load torque constant (constant torque)

Constant torque applications are applications such as compressors, machine tools, and cranes that require high torque at start-up and constant torque at low speed. The low-speed output power of the motors designed for these applications is kept as high as possible to meet the high torque requirement.

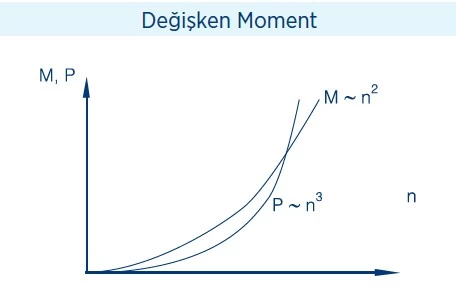

2. Load torque is proportional to the square of the speed (variable torque)

Variable torque applications are applications such as pumps and fans, which do not require high torque at start-up and whose torque requirement at low speed decreases with the square of the speed. In motors designed for these applications, the power ratio is approximately 1:4 when the rotation ratio is 1:2, and the power ratio is approximately 1:3 when the rotation ratio is 3:2.

In Dahlander wound motors, the Δ/YY connection is made for constant torque, and the Y/YY connection is made for variable torque. Y/Y connection is made in both applications in motors with two separate windings. Terminal end connections of the motors are as follows;

For detailed information, please contact us.